Helping to establish failure thresholds and 服务 life limits, high cycle fatigue (HCF) testing is an integral part of our aerospace engine qualification programs. 我们独特的, world-class capabilities enable us to handle everything from small sub-components to the largest fan blades in 服务 today.

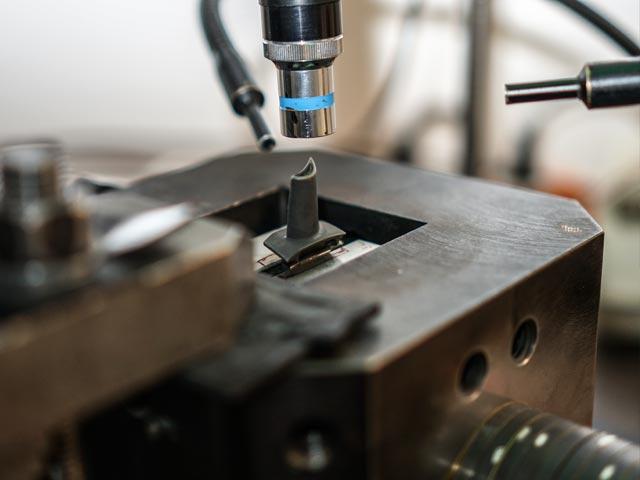

High vibrations conditions of airfoils during operation can impact the 结构 integrity of a test specimen, 为什么HCF测试必不可少. Individual metallic and future advanced material turbine blades or 段 of a bladed disk are tested in the natural resonance frequency range until crack initiation. Our equipment allows us to run a very high number of cycles in a short amount of time, 模拟组件的使用寿命. Our HCF testing 服务 portfolio also includes the ability to carry out strain gauge 校准 在仪表机翼上.

进行高周疲劳试验(HCF)

在HCF测试期间, individual turbine blades (or blade samples) are cycled at an extremely high rate to mimic their natural operating frequency. 一旦开裂开始发生, 记录故障周期计数, and the product is analyzed for performance characteristics and durability criteria.

We understand the unique environments and challenges that airfoils and aerospace engine components face. To better support your testing program, we offer a range of options for 高周疲劳试验, 包括在高达1200摄氏度的温度下进行测试, 样品开槽和加工服务, 夹具和夹具设计, 以及专业的测试方法.

High Cycle Fatigue 测试 for 航空航天 Engine Qualification

We support a range of high cycle fatigue test methods, including:

- 压电

- 摘要

- 常数Airjet

- 切碎的空气

- 声波疲劳(热/冷)

For more information about out 高周疲劳试验 programs, or to request a quote, 立即im体育APP.

相关服务

旋转测试

Find out how im体育APP tests all rotating components within aero engines to help make certain that they are safe and reliable when in-服务.

航空航天材料测试

As the largest independent materials testing provider in the global 航空航天 sector, im体育APP能够很好地满足您的每一个需求, 从早期R&D开发项目, materials testing for production through to solutions for in-服务 challenges.

动态测试

除了振动测试, im体育APP provides a range of dynamics testing including acceleration, 冲击, 下降, 结构, 疲劳和旋转载荷模拟.

翼型叶片

Find out about im体育APPs extensive range of High Cycle Fatigue (HCF) testing 服务 for engine airfoils.